£7m AI problem predictor project goes live

Artificial Intelligence which will predict when equipment across our water and wastewater networks is likely to fail is being rolled out at sites across our region

Using AI to improve performance

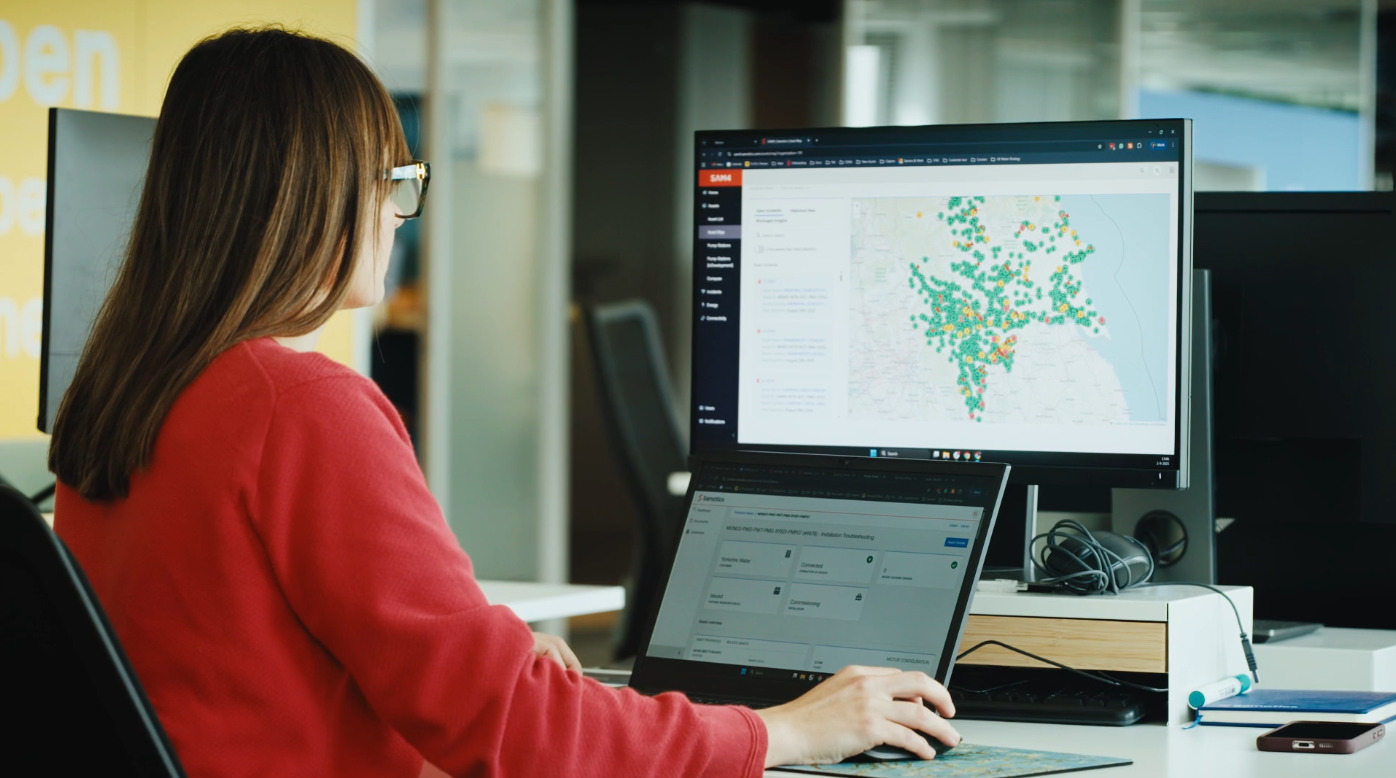

The £7 million six-year deal with Samotics will see SAM4 smart condition monitors installed, to help reduce the risk of loss of water supply incidents and possible pollution or flooding events.

The agreement, reached in autumn 2025, follows a successful year-long trial that demonstrated their effectiveness by detecting 63 equipment failures including air locks and and mechanical faults – helping to avoid an estimated £5 million in equipment damage and penalties.

Currently, 1,458 of our critical pieces of equipment are being monitored by Samotics’ technology across 600 sites and this will increase through 2026.

John Penicud, Managing Director for Wastewater at Southern Water said:

“Unplanned failures of critical equipment can lead to a negative impact on our customers and the environment, and result in increased operational costs. Identifying issues early is critical to successful proactive maintenance.”

Tom Swain, Head of UK and Ireland at Samotics said:

“We’re absolutely delighted to enter this long-term partnership with Southern Water, who continue to lead the industry in using advanced technologies to prevent asset failure.

“AI algorithms interpret deviations from normal operation and classify them into specific fault types, such as misalignment, bearing wear or pump clogging, which predicts equipment failure.

“This strategic initiative represents a major step forward in modernising metering infrastructure. It enhances insight, improves water efficiency, improves network performance and supports environmental sustainability.”

Samotics’ SAM4 uses Electrical Signature Analysis and AI algorithms to continuously deliver detailed, actionable insights into the condition and performance of assets.

SAM4 detects equipment issues frequently dealt with by water utilities - such as misalignment, bearing wear, or pump blockages - from the motor control cabinet, without needing direct access to assets.