Some of our online services will be unavailable today between 3pm and 10pm due to essential maintenance. We apologise for any inconvenience this may cause. Our chat services will remain available to assist with water and wastewater queries.

Isle of Wight Water Recycling Project Planning Application

Southern Water has submitted plans for a water recycling plant at Sandown on the Isle of Wight that will be the UK's first full-scale water recycling plant to use an integrated membrane treatment process.

Southern Water has submitted plans for a water recycling plant at Sandown on the Isle of Wight that will be the UK's first full-scale water recycling plant to use an integrated membrane treatment process.

Called the Isle of Wight Water Recycling Project, it will use advanced treatment techniques to turn treated wastewater into 10.8 million litres of purified recycled water a day.

This purified recycled water would be released into the Eastern River Yar. Water taken from the river downstream would be treated again at Sandown Water Supply Works to produce up to 8.5 million litres of drinking water a day.

Some of the purified recycled water will be left to continue down the full length of the river so there’s more water for wildlife, at a time when the levels would have been lower.

As well as creating a new source of water for customers on the Isle of Wight, the project will reduce the amount taken from the delicate River Test on the mainland. The River Test currently supplies one-third of the Island’s water via the Cross-Solent Main.

Ben Ring, Major Projects Director at Southern Water, said: “This essential project is part of a series of schemes that will create new drought-proof sources of water.

“These new sources will help us protect Hampshire’s chalk streams, maintain supplies for our customers and provide greater resilience for the Island.

“The project has been many years in the making. Submitting the planning application to the Isle of Wight Council is a significant milestone for Southern Water and also for the UK.”

Purified recycled water will be produced at the site using an integrated membrane treatment process comprising a membrane bioreactor and reverse osmosis, followed by ultraviolet advanced oxidation and remineralisation.

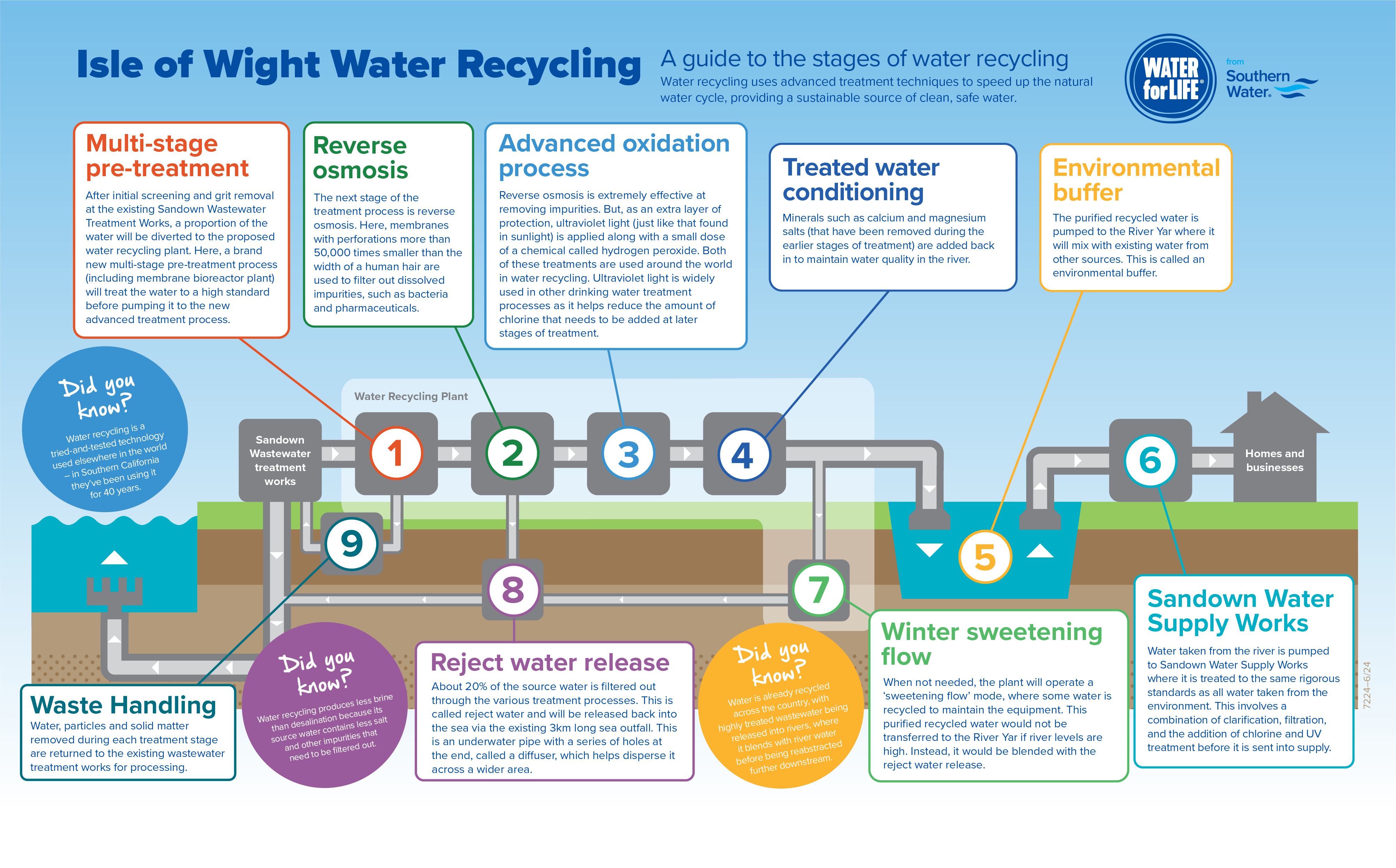

Isle of Wight Water Recycling Project – a step-by step guide through the process.

1. Multi-stage pre-treatment process: including a membrane bioreactor which produces high quality treated wastewater.

2. Reverse osmosis: water is pumped at pressure through a membrane with holes more than 50,000 times smaller than the width of a human hair, to filter out dissolved impurities.

3. Advanced Oxidation: water is treated with ultra-violet light and hydrogen peroxide.

4. Treated water conditioning: water is remineralised to add back in the beneficial minerals removed by reverse osmosis.

5. Environmental buffer: the purified recycled water is transferred into the Eastern River Yar where it will mix with river water.

6. Sandown Water Supply Works: water taken from the river downstream is treated to strict drinking water standards before being supplied to customers.

7. Winter sweetening flow: the plant operates at a lower capacity when not in drought to ensure the equipment is maintained and ready for use when needed.

8. Reject water release: about 20% of the source water is filtered through the treatment process and is released via an existing outfall 3km out to sea.

9. Solids removed in the process will be treated at the Sandown Wastewater Treatment Works.